This article shows how to install a smoke system for mid-size 4-stroke engines without using a pump. I have used it on .52 to .91 sized engines with good success.

Weight and space are at a premium for planes in this engine range and a pumpless system saves on both. It also is less costly than a pumped system.

The principle is to use the muffler to pressurize the smoke tank, a one-way check valve to keep the pressure in, and then a servo to let the smoke oil out, into the muffler. I use a modification of the system sold by Macs Products (www.macspro.com).

Muffler pressure is not just "out". The engine produces an intake and an exhaust phase which in turn creates an "in-and-out" pressure within the muffler while the engine is running. This is how the muffler can both suck smoke oil in and push pressure out, seemingly at the same time.

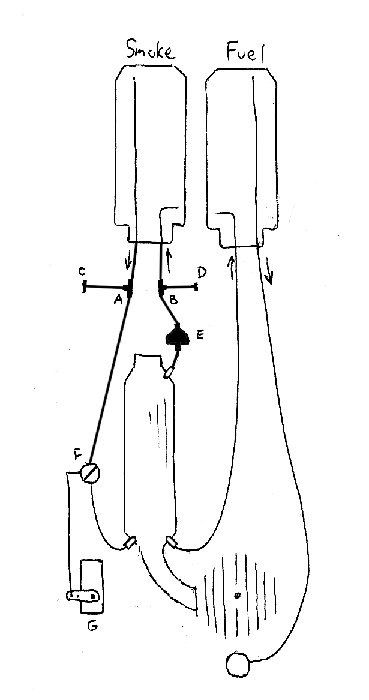

| The materials I used are: - A second fuel tank for the smoke oil. You will need to purchase a gas conversion stopper for it. - Neoprene fuel tubing - 1 Perry aluminum check valve (VP-2CV) or equal - 1 Perry Remote Smoke Valve (VP-RSV-04) or equal - 1 servo - 2 additional pressure nipples for the muffler - 2 "T" fittings - 2 fuel line plugs Sullivan makes some nice fuel tanks called "Slant Oval". They are normal height but a 10 oz. tank is only an inch and a half wide. You can fit two of these next to each other in the space allotted for one regular tank. The cost of all materials not including the tank and servo is about $40.00. The diagram to the right best explains the plumbing where: Note that the positioning of the pressure nipples is on the angled portion of the muffler. The one going to the fuel tank is the one that comes with the muffler. The holes for the other two need to be drilled and tapped. To fill, close the smoke valve (F), unplug the fuel lines at C and D and fill the tank at C. If you forget to close the valve, the smoke oil will come out the muffler instead of going into the tank. If you forget to unplug D, something will pop since there is no way for the displaced air to escape as you fill the tank.

The Macs Products system uses a different on-off valve, one that stops the pressurization of the tank when the smoke is off. The theory is there was a possibility that too much pressure could build up. I found the smoke to be weaker with this system and pressure build-up has not been a problem, though I keep the smoke mostly on until it runs out. While flying, it is important to keep the throttle at nearly full since this is the best way to generate pressure. A low pitch, high diameter prop will get you the slowest speed with the highest RPM's. I use a 15 x 6 for a .91 Surpass. The smoke lasts nearly as long as the fuel so when the smoke runs out I know it's time to set up for a landing. Super-Dri Smoke Oil seems to work best and there is no HazMat fee for shipping it. |

|

Here are some photos of the installation:

(Click the thumbnails below)

Photo Gallery |

Home | Desktop Pictures

Moon Photos |

Radio Control Airplanes | Stereograms